Manufacturing Strength

HTEGPL leads the market segment with technical expertise, in fields such as custom designed cylinders, Tie Rod Cylinders, Mill Duty Cylinders, high-speed or zero-leakage technology cylinders, Servomotors, Offshore Onshore Specialized Cylinders.

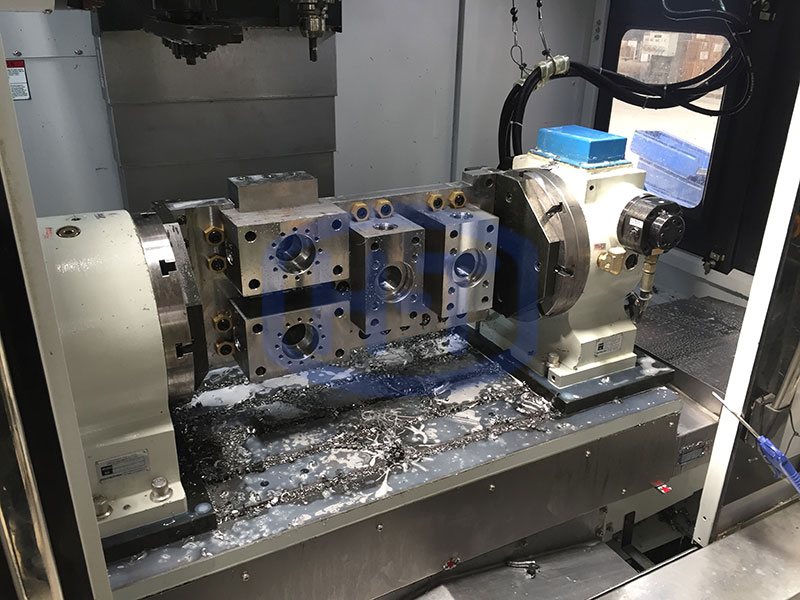

Our Production facilities include, CNC Turning Machines, Vertical Machining Centers, Turnmill Centres, Positional 5 axis Machines, large grinding machine, vertical honing, polishing machines, welding machines etc. Most of our machines are digitally computerized (CNC).

HTEGPL are capable of designing any type of custom hydraulic cylinders, as per the customer’s requirements, as long as it fits in our wide manufacturing capabilities, which are:

Bore diameter ( I.D.): Up to 1000mm

External diamter (O.D.): Up to 1250mm

Length: Up to 7000mm

Welding: TIG/GTAW ( Gas Tungsten Arc Welding), MID/GMAW(Gas Metal Arc Welding), SAW( Submerged Arc Welding)

Test Bench: HTEGPL has a state of the art test bench, capable of testing 4 cylinders simultaneously along with drag test capabilities and the results

are plotted electronically via graph.